"Fichtner H2-Optimizer": Powerful New Tool for Optimizing Hydrogen Systems

How should an electrolyzer be designed and operated? What is the optimal H2 storage capacity? How high are the hydrogen production costs? Is it all worth it economically? - The "Fichtner H2-Optimizer" provides answers to these questions.

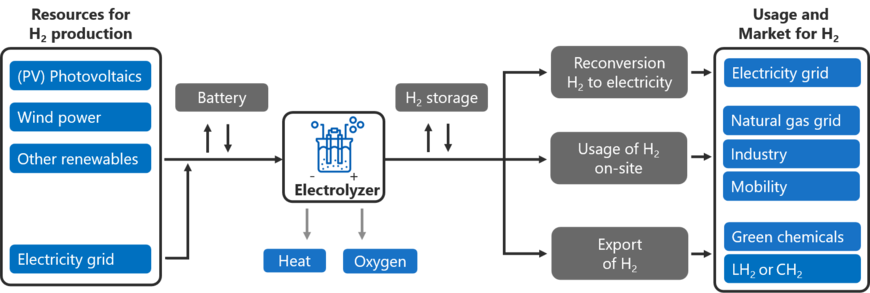

The "H2-Optimizer" was developed by Fichtner's hydrogen experts as a powerful optimization tool. With its help, parameters such as the hydrogen production costs can be calculated and individual complex components of your hydrogen project such as electrolyzer, storage and power generation capacities can be technically dimensioned. In addition, the mapping of various sales markets is made possible. The tried and tested tool draws on demand, power generation and price profiles and calculates the best possible combination of technologies for your project on the basis of modeling of various technical options. All of this takes place taking into account the applicable framework conditions of the respective hydrogen system and the underlying value chain.

In this way, the H2-Optimizer gives you a comprehensive overview of your hydrogen system. The optimal use of each component is evaluated by Fichtner's experts and clearly prepared for you.

In use worldwide

The H2-Optimizer is used worldwide for numerous hydrogen projects and supports individual customer requirements. The project-specific modeling is always supervised by Fichtner's hydrogen experts. We would therefore like to give you an insight into two hydrogen projects that our H2-Optimizer is successfully supporting:

1. Innovative project for sector coupling with H2

In this project, Fichtner has been contracted as owner’s engineer by the client ‘TIWAG’ to design and engineer an innovative power-to-X plant in Kufstein, Austria which will produce both hydrogen and heat. This will be achieved with the help of power drawn from TIWAG’s own ‘Langkampfen’ run-of-river hydropower plant, from its own solar plant and from the grid. In addition to the waste heat from electrolysis in the power-to-gas plant, the extra heat from the power-to-heat plant is to be fed into the city of Kufstein’s district heating grid. The hydrogen produced will be delivered to end customers at the associated hydrogen filling station or to large customers via trailer or direct pipeline. There are a great many variables to consider in this project as well – both on the power generation and heat offtake side as well as on the projected hydrogen sales side.

Using the H2-Optimizer, our hydrogen team managed to model and optimize the plant concept for TIWAG in the design phase.

You can find out more about this project here.

2. Feasibility analysis on producing green hydrogen in India and processing it into green methanol and ammonia

Producing green chemicals such as methanol and ammonia is becoming increasingly important in India due to the increasing share of renewable energy sources and international efforts towards decarbonization. For this reason, a feasibility report in cooperation with Fichtner India for a large Indian energy supplier and an international technology supplier served to demonstrate the production of green hydrogen from the feed of a floating PV system of the local energy supplier in Ramagundam. The H2-Optimizer provided effective support for this project. Many options for power procurement were assessed, and the optimum plant layout was selected based on the results. Ultimately, the hydrogen produced can be used for ammonia and methanol production.

Would you like your future project to follow suit? Or do you already have a specific request and would like more information about the H2-Optimizer? Contact Dr. Florian Klumpp and our hydrogen team at hydrogen@fichtner.de . We look forward to supporting you in your projects.

All information about the H2-Optimizer is also available in a compact bundle in the new H2-Optimizer Flyer.